Why Choose Birmingham Metal?

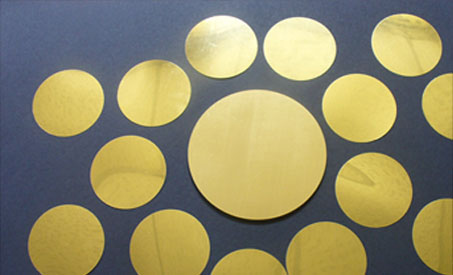

At Birmingham Metal., we specialise in manufacturing high-quality sputtering targets made from precious metals, including gold, silver, platinum, and palladium. Our products are:

- Customisable: Tailored to meet the unique demands of your industry and applications.

- High-Purity: Adhering to strict ISO 9001 quality standards to ensure reliable performance.

- Eco-Friendly: We offer comprehensive recycling services to help you recover value from used materials.

At Birmingham Metal, we also offer a precious metal reclaim service to enable the customer to achieve a fast, economic way of recycling scrap at preferential rates.

One of the unique properties of precious metals is that they can be recycled without a loss in quality. The recycling of precious metals is important as world reserves are limited and very much in demand with prices constantly increasing.

We can recycle a broad range of precious metals and alloys, in all shapes and sizes, and thanks to our close network of international metal processors, we also facilitate the recycling of low-grade, contaminated materials.

Our recycling process starts with the initial weighing of the batch of material on calibrated scales, which is recorded on our system. Subsequently, a comprehensive metal analysis is conducted to determine the optimal recycling procedure and to estimate the yield.

After the recycling process, the metals are weighed again, and the final yield is determined. The value of the reclaimed metal can then be credited against the customer’s account to offset any outstanding balances or, if the account is already clear, payment can be issued instead.

Alternatively, the metal can be held in a ‘pool account’ ready to be used in the manufacture of future orders. This option further promotes the cyclical use of precious metal resources.